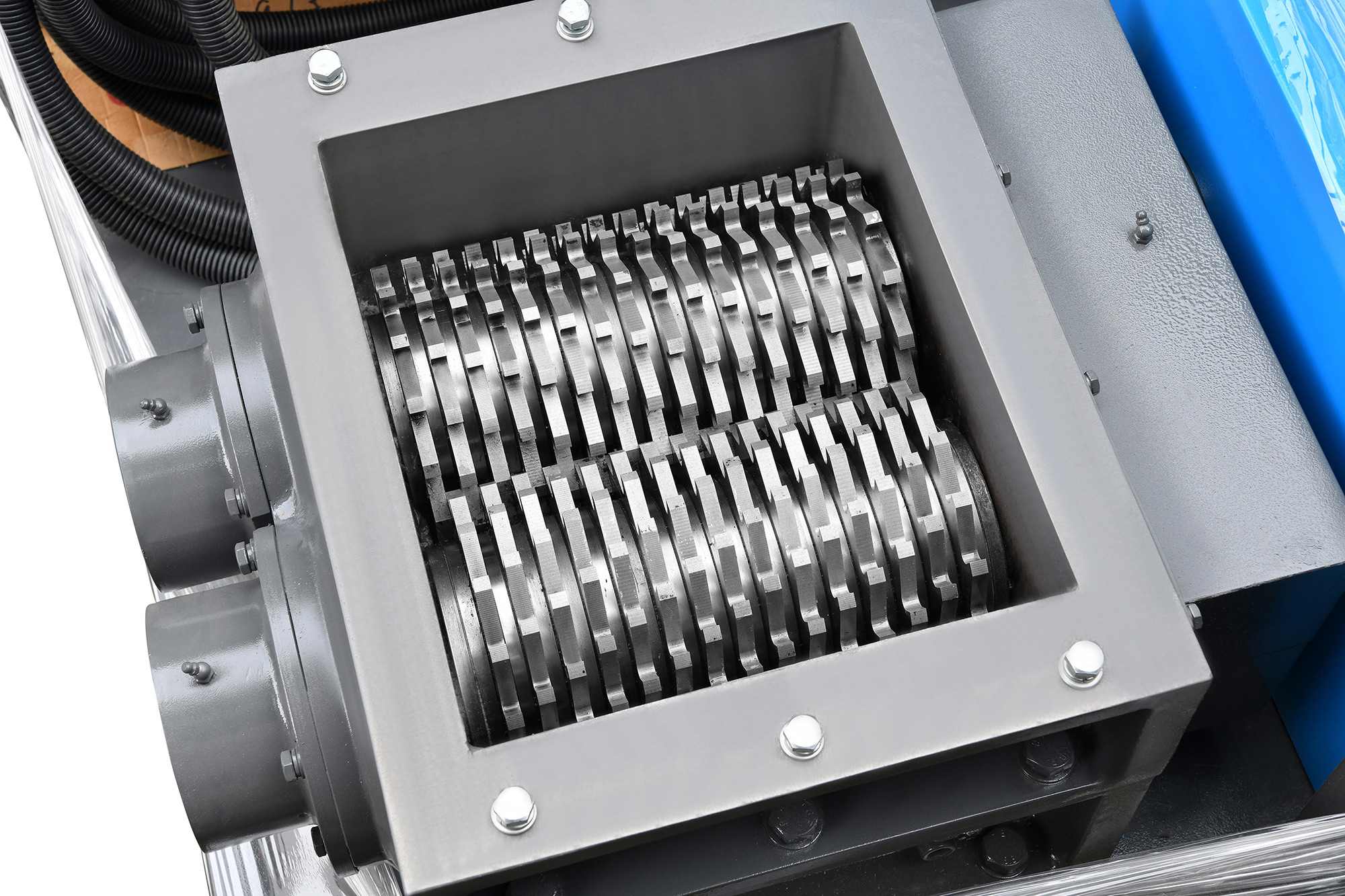

Double shaft shredder is a crushing equipment specially designed for the material with larger volume, thickness and hardness.Adopt low speed, high torques hearing design has the advantages of lownoise, low energy consump ton and high output.HSC double shaft shredder can be used as the so luton of coarse crushing incomplete recovery production line.Ultra-low speed and super torque; Integral/combined blade; Hydraulic forced feeding system.

Functions:

1. Ultra-low speed, super torque, 5~13 revolution spe minute; Low noise and dust

2. Choose two configurations of motor or hydraulic motor. According to different properties of broken materials,customers are free to choose integral shredding blade or assembled detachable blade

3. The advanced Simulation software Simulation can be used to ure the mechanical structure of the integral or combined blade to avoid fracture and disintegration

4.Hydraulic forced feeding device is sekected to tearo up materials more efficiently and quickly

5. Double locking structure at both ends of shaft head to ensure installation position of blade and prevent axial displacement

6. Put into product on 2~4 hours before delivery to ensure the reliability of equipment

Applications:

1.Plastic

2.Rubber products

3.The textiles

4.Paper products

5.Wood

6.Electronics

7.Metalwork

8.Wires and cables